Imveliso eyoNgezelelweyo kunye nokuVelisa okuThathayo: Ingxoxo ngokuSebenziswa kweMibungu emva koMachining ochanekileyo.

Imveliso yanamhlanje yemizi-mveliso ibeke phambili iimfuno eziphezulu zokuchaneka, ukusebenza kakuhle kunye nenkululeko yoyilo. Ukongeza kwitekhnoloji yemveli yokuvelisa (ezifana nokugaya, ukugaya, njl.),ukuveliswa okongeziweyo (ushicilelo lwe-3D)itekhnoloji ibuye ivele ngokukhawuleza kwaye ibe yindlela ebalulekileyo yokwenza izinto ezintsha. Zombini zineengenelo zazo kwaye zisetyenziswa ngokubanzi kwimimandla yeemoto, i-aerospace, izixhobo zonyango kunye nokuveliswa koomatshini. Kwezi ndlela zimbini zokuvelisa, indima yokubumba ibaluleke kakhulu kwaye ihambelana ngokuthe ngqo nomgangatho wokuqhuba kunye nokusebenza kakuhle kwemveliso.

Intshayelelo kwiTekhnoloji yokuVelisa okoNgezelelweyo kunye neSicelo seMold

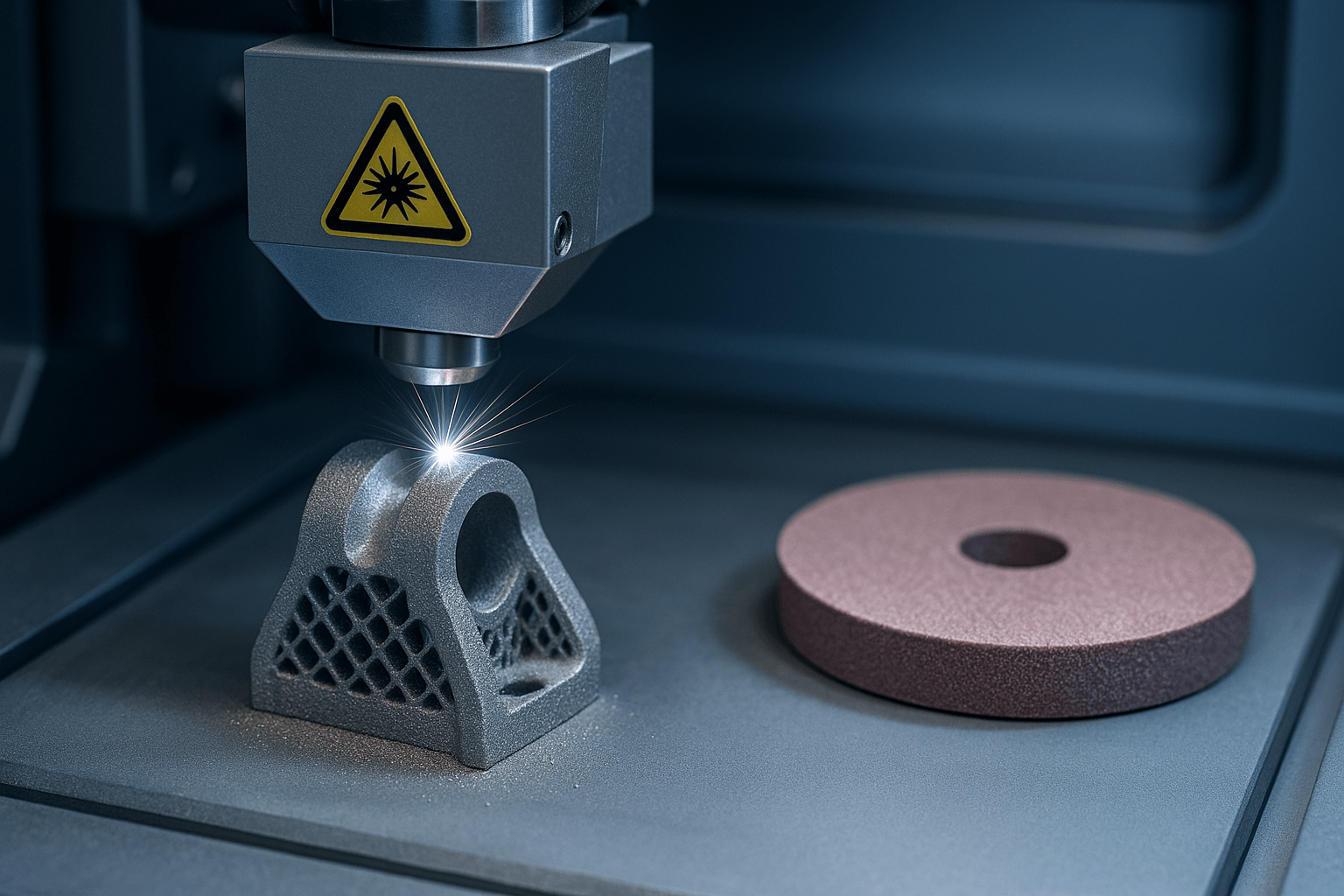

Imveliso eyongezelelweyo, eyaziwa ngokuba yi-3D yoshicilelo, yinkqubo yokwakha iinxalenye ngokupakisha izinto zomaleko ngokwemaleko. Ubuchwephesha obuqhelekileyo bokuvelisa i-laser sintering (SLS), i-laser melting ekhethiweyo (SLM), i-fused deposition modeling (FDM) kunye ne-stereolithography (SLA). Olu hlobo lobuchwephesha lwaziwa ngenkululeko yoyilo oluphezulu kakhulu. Inokwenza iinxalenye ezinemilo enzima kunye nemingxuma yangaphakathi okanye izakhiwo zegridi, ngokusetyenziswa kwezinto eziphezulu kunye nokunciphisa kakhulu inkunkuma yezinto. Imveliso eyongeziweyo ifanelekile ngokukodwa kwiprototyping ekhawulezayo, imveliso yebhetshi encinci kunye nokwenza ngokwezifiso, kwaye isetyenziswa ngokubanzi kwi-aerospace, iimoto, izixhobo zonyango kunye nokuveliswa kokungunda. Iinzuzo zayo zikwabandakanya ukunciphisa umjikelo wophuhliso, ukukhuthaza ukuyila okutsha kunye nokuphunyezwa kwezisombululo ezahlukeneyo.

Nangona ukuveliswa okongeziweyo kunokwenza ngokuthe ngqo izakhiwo ezintsonkothileyo, umphezulu wamacandelo ashicilelweyo udla ngokuba rhabaxa, kunye nemigca yomaleko kunye neziphene ezincinci, kwaye umatshini olandelayo uyafuneka ukuhlangabezana nobungakanani kunye neemfuno zomgangatho womphezulu. Ngeli xesha, iibrasives ezisebenzayo ziba zizixhobo eziphambili. Abrasives ezifanaamavili okusila, amabhanti e-sanding, amavili e-flap kunye namavili okupholisha asetyenziswa ngokubanzi ukuchithwa, ukucolwa komhlaba kunye nokugqitywa kweendawo zokuvelisa ezongezelelweyo ukuqinisekisa ukuba iimveliso zifikelela ukuchaneka kwe-industrial-grade kunye ne-aesthetics. Ngokukodwa kwiinkalo ze-aerospace kunye nezonyango, iimfuno eziphakamileyo zomgangatho ophezulu kunye nokusebenza ziye zaqhubela i-abrasives ukuba iqhubeke nokuphuhlisa izinto eziphezulu kunye nezixhobo eziphezulu zokunxiba ukuze zihlangabezane neemfuno ezikhethekileyo zokwenza i-additive production post-processing.

Intshayelelo kwitekhnoloji yokuvelisa i-subtractive kunye ne-abrasive application

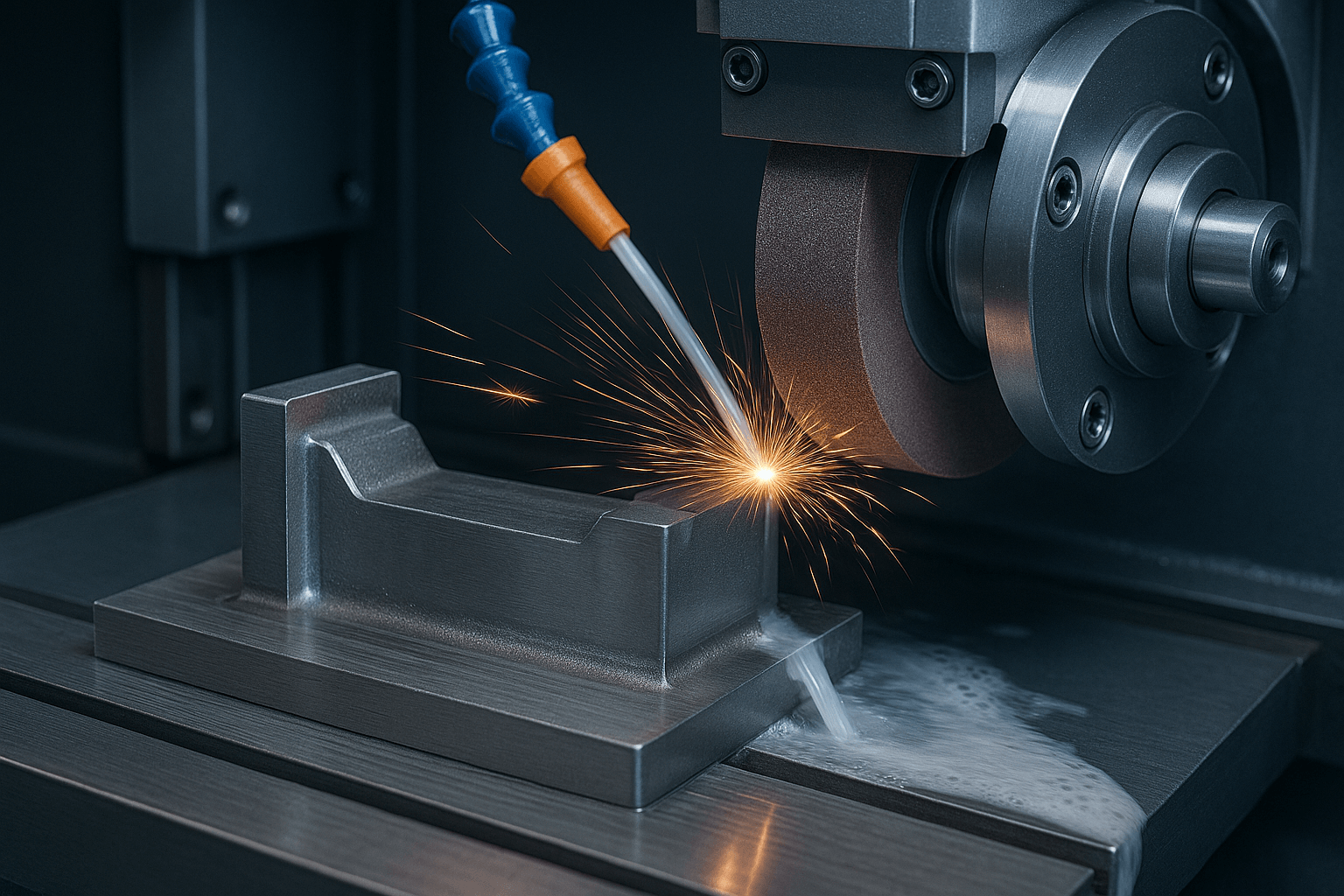

Ukwenziwa kwemvelisokukususa imathiriyeli engaphezulu ngokusika, ukusila, ukucola kunye nezinye iindlela zokusetyenzwa kwesixhobo sokusebenza sibe similo esele simisiwe. Le teknoloji ikhulile kwaye ifanelekile kwimveliso yobuninzi, ngakumbi ilungile ekuqinisekiseni imilinganiselo echanekileyo ephezulu kunye nomgangatho obalaseleyo womphezulu. Iinkqubo eziqhelekileyo ziquka ukugaya i-CNC, ukuguqula, ukugaya, ukusika ucingo, ukuchithwa kombane (EDM), ukusika i-laser kunye nejethi yamanzi. Imveliso ethotywayo idlala indima ephambili kwimveliso yeemoto, i-aerospace, ukwenziwa koomatshini kunye nezixhobo zonyango. Iyakwazi ukusebenza ngokufanelekileyo intsimbi, intsimbi, i-aluminium alloys kunye nezixhobo ezidibeneyo ukuhlangabezana neemfuno ezingqongqo zeshishini lokuqina kunye nokusebenza.

I-Abrasives idlala indima esisiseko kunye neyona nto ibalulekileyo kwimveliso ekhuphayo, ngakumbi kwinkqubo yokugaya. Iindidi ezahlukeneyo zamavili okusila (ezifana namavili e-ceramic okugaya, i-resin bonded grinding wheels) kunye nezixhobo zokugulisa zisetyenziswa ngokubanzi kumatshini obukhali, ukugqiba kunye nokugulisa umphezulu ngokweemfuno zenkqubo ukuqinisekisa ukuba iindawo zifezekisa ukuchaneka okuphezulu kunye nomgangatho wesipili somgangatho ophezulu. Ukusebenza kwe-abrasive kuchaphazela ngokuthe ngqo ukusetyenzwa kwemveliso kunye nomgangatho wemveliso, ikhuthaza ukusungulwa okuqhubekayo kwezinto ezinqabileyo kunye nezakhiwo ukuhlangabezana neemfuno zokulungiswa kwezinto ezinobunzima obuphezulu kunye neejometri ezinzima.

Njengebhulorho ebalulekileyo phakathi kwezi zimbini, iibrasives zixhasa uqhagamshelo olungenamthungo ukusuka kwimveliso eyongezelelweyo ukuya kwimveliso ethabathayo. Ngokusetyenziswa okunyukayo kwezinto ezidibeneyo kunye nezinto ezinobunzima obuphezulu, ukuphuculwa kobuchwephesha be-abrasive kuye kwaba likhonkco eliphambili ekuqinisekiseni umgangatho wokuvelisa. Ukuphendula kwiingxaki zobunzima bomphezulu okhethekileyo kwimveliso eyongeziweyo kunye neemfuno ezichanekileyo ezichanekileyo zokwenziwa kwemveliso ethatyathiweyo, uphando kunye nophuhliso lokungunda luyaqhubeka nokuphuhlisa ubulukhuni obuphezulu, ubume obungcono kunye nobomi obude, ukukhuthaza ubukrelekrele kunye nokusebenza kakuhle kwekhonkco lokuvelisa lonke.