Iimveliso

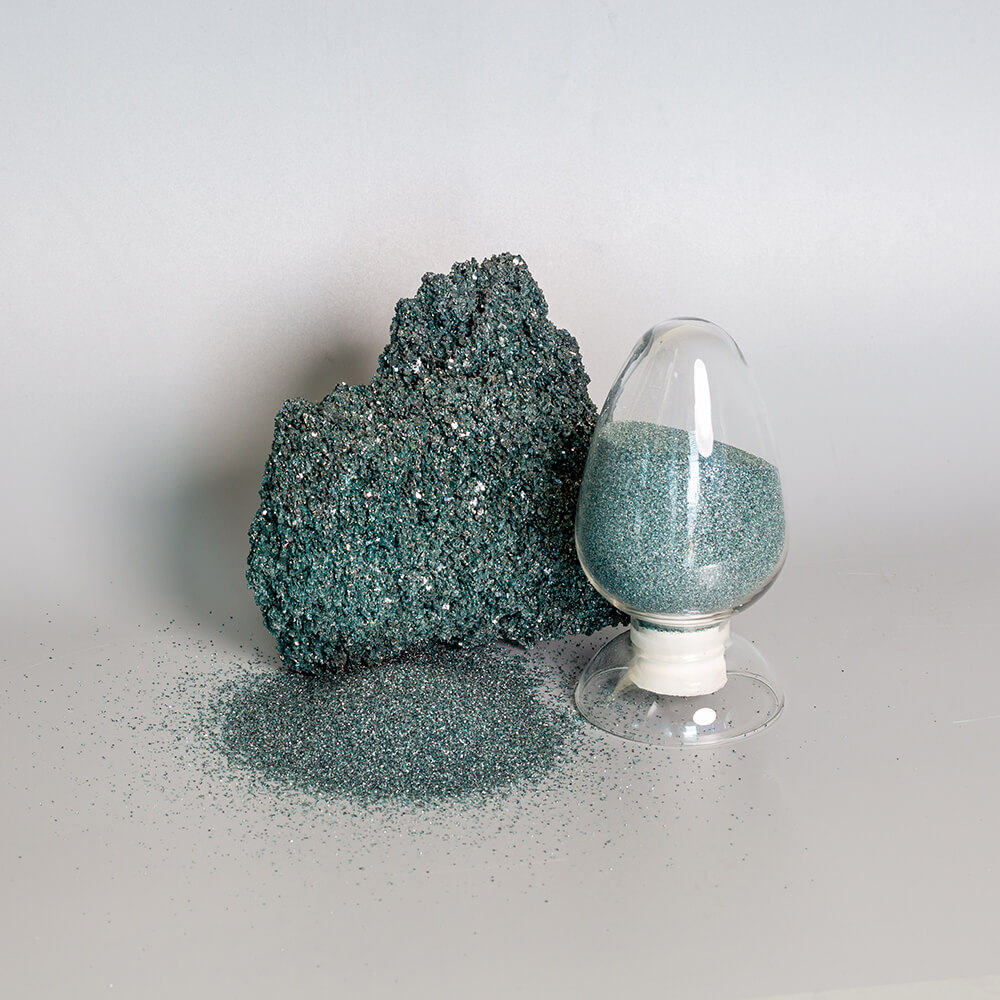

I-Silicon Carbide Powder eluhlaza ye-Bonded Silicon Carbide Ivili lokuSila

Inkcazo ye-silicon carbide eluhlaza

Isilicon carbide eluhlaza yenziwe ngesanti yequartz kunye nepetroleum coke ngokunyibilika kobushushu obuphezulu.Indlela yokuvelisa ngokusisiseko iyafana naleyo ye-silicon carbide emnyama, kodwa iimfuno zemathiriyeli ekrwada zahlukile.Iikristale ezinyibilikisiweyo zinobunyulu obuphezulu, ubunzima obuphezulu kunye namandla anamandla okusika, kwaye zifanelekile ukucubungula izinto ezinzima kunye ne-brittle.I-silicon carbide eluhlaza ilungele ukugaya i-alloys eqinileyo, isinyithi esiqinileyo kunye ne-brittle kunye nezixhobo ezingezizo zetsimbi, ezifana neentsimbi ezingenayo i-ferrous ezifana nobhedu, ubhedu, i-aluminiyam kunye ne-magnesium, kunye nezinto ezingezo zetsimbi ezifana namatye anqabileyo, iglasi ye-optical kunye neekeramics. .

| Iimpawu zePhysical | |

| Umbala | Luhlaza |

| Ifom yeCrystal | Ipolygon |

| Mohs ubulukhuni | 9.2-9.6 |

| Ubulukhuni obuncinci | 2840~3320kg/mm² |

| Indawo yokunyibilika | 1723 |

| Ubushushu bokusebenza okuphezulu | 1600 |

| Ubuninzi bokwenyani | 3.21g/cm³ |

| Unizi lolwapho kuyiwa khona | 2.30g/cm³ |

| Ukuqulunqwa kweekhemikhali | |||

| Iinkozo | Ukwakheka kweekhemikhali(%) | ||

| Sic | FC | Fe2O3 | |

| 16#--220# | ≥99.0 | ≤0.30 | ≤0.20 |

| 240#--2000# | ≥98.5 | ≤0.50 | ≤0.30 |

| 2500#--4000# | ≥98.5 | ≤0.80 | ≤0.50 |

| 6000#-12500# | ≥98.1 | ≤0.60 | ≤0.60 |

1.I-Abrasive: iimoto, i-aerospace, isinyithi, kunye nobucwebe.Isetyenziselwa ukuguba, ukusika, kunye nokupolishwa kwesinyithi esiqinileyo kunye neeseramikhi.

I-2.I-Refractory: i-furnaces kunye ne-kilns ngenxa ye-conductivity ephezulu ye-thermal kunye nokwandiswa kwe-thermal ephantsi.

I-3.I-Electronics: ii-LED, izixhobo zamandla, kunye nezixhobo ze-microwave ngenxa ye-conductivity yayo yombane egqwesileyo kunye nokuzinza kwe-thermal.

4.Amandla elanga: iiphaneli zelanga

5.Metallurgy

I-6.IiCeramics: izixhobo zokusika, iindawo ezinqabileyo zokunxiba, kunye namacandelo aphezulu okushisa

Umbuzo Wakho

Ukuba unayo nayiphi na imibuzo.Nceda uzive ukhululekile ukuqhagamshelana nathi.