Iimveliso

Idayimani eyokwenziwa iPowder eNgcwelisiweyo

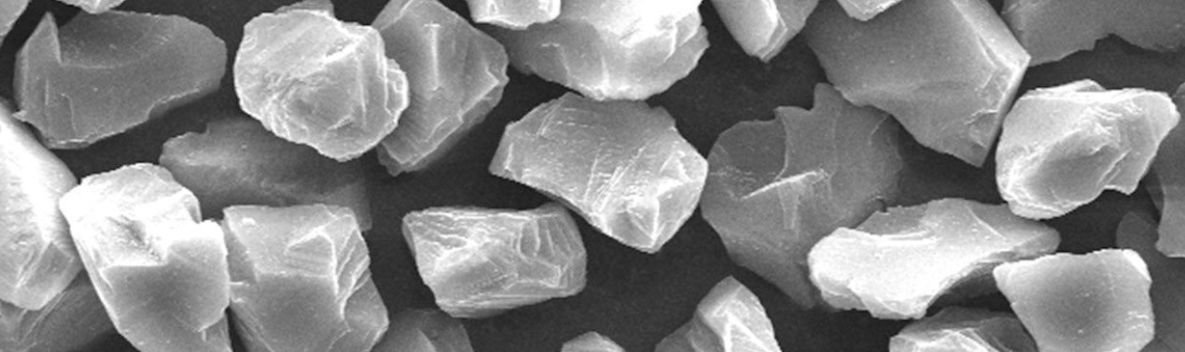

I-Monocrystalline Diamond Powder

I-Monocrystalline Diamond Powder iveliswa kwidayimane eyenziweyo ye-crystal abrasive grains nge-static pressure method, etyunyuzwayo kwaye ibunjwe ngokusebenzisa inkqubo ekhethekileyo yezinto ezilukhuni kakhulu. Amasuntswana ayo agcina iipropathi zekristale enye yedayimani yekristale enye.

| Inkcazo | D50 (μm) | Inkcazo | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

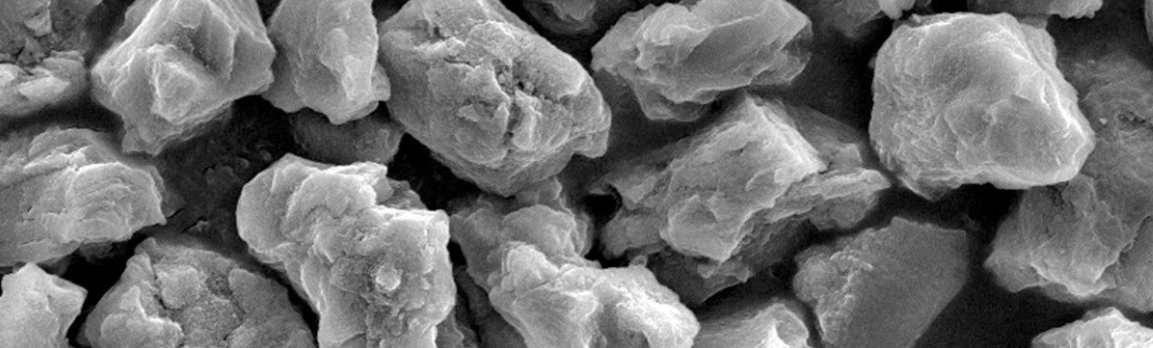

Polycrystalline Diamond Powder

I-polycrystalline diamond powder yi-micron kunye ne-sub-micron polycrystalline amasuntswana enziwe ngeenkozo zedayimani ezinobubanzi obuyi-5 ~ 10nm ebotshelelwe kwiibhondi ezingaxutywanga. Ngaphakathi i-isotropic kwaye ayinazo iinqwelomoya eziqhekezayo. Inokuqina okuphezulu. Ngenxa yeempawu zayo ezikhethekileyo zesakhiwo, ihlala isetyenziselwa ukugaya kunye nokupholisa izixhobo ze-semiconductor, ii-ceramics ezichanekileyo, njl.

Ubungakanani obukhoyo bedayimane yomgubo omncinci bunje ngezantsi:

Iimpawu zeMveliso

-Ubukhulu obugqithisileyo bususwe ngokupheleleyo

-PSD emxinwa

-Ukucoceka komphezulu kunokufikelela kwinqanaba le-ppm

-Dispersibility ebalaseleyo

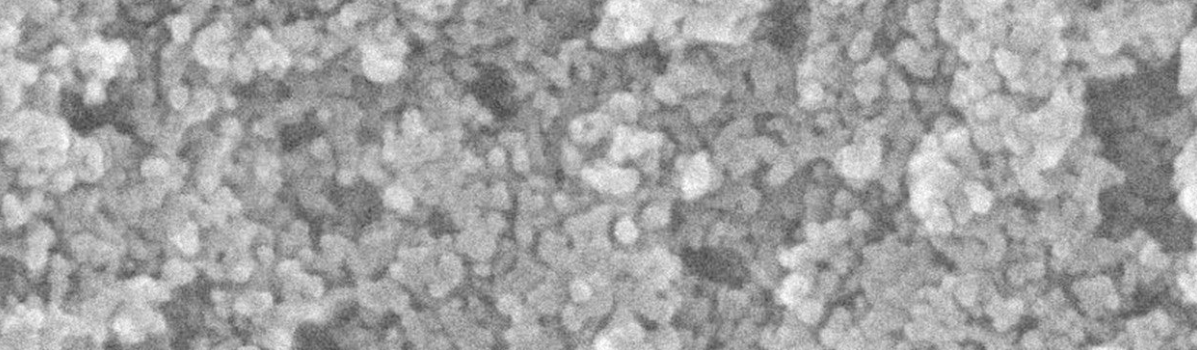

Nano Diamond Powder

Umgubo wedayimani weNano wenziwa ngeekristale ezincinci ezingaphantsi kwe-nanometer engama-20, imeko ekhethekileyo yokuqhawuka ivelisa idayimani emile okwengqukuva eneqela elityebileyo elisebenzayo kumphezulu, indawo yayo ethile yongezwa ngomyalelo omnye wobukhulu ngokuchasene nedayimani ye-monocrystalline. Le mveliso ayinayo kuphela ubunzima obuhle kunye neempawu zokugaya zedayimane, kodwa ineempawu ezintsha zezinto ezingasebenziyo.

| Ubukhulu | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Iimpawu

Isicelo seMonocrystalline Diamond powder

1. Ilungele iingcingo ezahlukeneyo zedayimani ze-electroplated ezichanekileyo, i-electroplated diamond grinding wheels, i-SiC crystal cut, iimela, ii-ultra-thin saw blades, njl.

2. Ifanele i-diamond composite sheets, i-diamond polycrystalline kunye neemveliso zebhondi yentsimbi, iimveliso ze-ceramic bond, iimveliso zedayimane ze-electroplated, njl.

3. Ilungele izixhobo zedayimani ezixutywe nge-electroplated, amavili okugaya, njl njl.

4. Ukulungeleka ngokuchanekileyo ukugaya kunye nokupholishwa kwamatye anqabileyo aphezulu, iilensi, izinto ezisetyenziswayo ze-metallographic, iipaneli ze-LCD, i-LCD glass, isafire, i-quartz sheets, i-LED substrates yesafire, iglasi ye-LCD, izinto ze-ceramic, njl.

Izicelo zePolycrystalline Diamond powder

1.Ubhityile kunye nokupolisha kweewafers zesemiconductor, njengeSiC wafer kunye nesafire.

2.Ipolishi yomphezulu yezinto ezahlukeneyo ze-ceramic

3.Ukukhazimliswa komphezulu wezinto zetsimbi, njengentsimbi engatyiwa, ingxubevange yealuminiyam njalo njalo.

Izicelo zeNano Diamond Powder

1. Ukugulisa kakuhle kakhulu. Uburhabaxa bomphezulu bezinto zokusebenza ezipolishiweyo zinokufikelela kwinqanaba le-angstrom ngaphandle kwemikrwelo, enokwanelisa eyona mfuno ingqongqo yezicelo zokupholisha.

2. Idayimani yeNano ingasetyenziswa njengezongezo zeoli yokuthambisa. I-sliding friction iya kutshintshwa ibe yi-rolling friction, enokuthi yehlise i-coefficient ye-friction kwaye iphucule ngokubonakalayo ukusebenza kwe-friction kunye nokwandisa ubomi benkonzo.

3. I-Composite plating kunye nokutshiza kumphezulu wezinto ezahlukeneyo zokusebenza, ukukhulisa ukunganyangeki, ukuxhathisa ukubola, ukuqina kwempembelelo kunye nokuqina komphezulu wezixhobo zokusebenza.

4. Njengezongezo zerabha kunye neeplastiki, idayimani ye-nano inokwandisa kakhulu ukuxhathisa kwayo, ukuxhathisa i-puncture, ipropathi eqinile kunye nokucothisa inkqubo yokuguga.

5. Ucoceko oluphezulu lwedayimani ye-nano ayiyi kubangela ukugatywa kwezinto eziphilayo, okwangoku inokusetyenziswa ngokubanzi kwiinkalo zonyango, zebhayoloji kunye ne-cosmetic ngenxa yendawo enkulu ethile, i-adsorption enamandla.

Umbuzo Wakho

Ukuba unayo nayiphi na imibuzo.Nceda uzive ukhululekile ukuqhagamshelana nathi.