Iimveliso

Platelet Calcined Alumina Powder

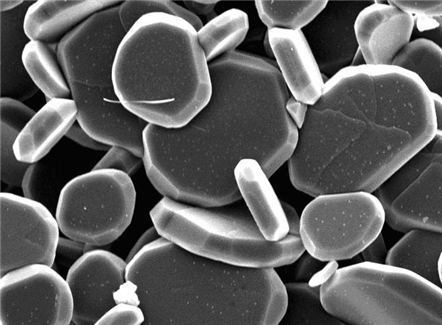

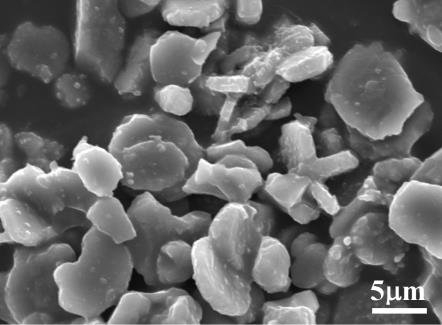

I-Plate Calcined I-Alumina ipolishi yokupholisha yenziwe nge-alumina esemgangathweni ye-industrial powder njengento ekrwada, kwaye iqhutywe yinkqubo ekhethekileyo yokuvelisa.Ubume bekristale bemveliso ye-alumina ipolishi yomgubo i-hexagonal flat efana ne-tabular shape, ngoko ibizwa ngokuba yi-Platelet Alumina okanye i-Tabular Alumina.

I-Platelet Alumina yi-alumina esemgangathweni ophezulu wohlobo lwe-abrasive powder, equkethe i-crystal emise okweplate ye-Al2O3 enobunyulu obungaphezu kwe-99.0%.Ineempawu ezibalaseleyo zokumelana nobushushu kunye nokungangeni kwikhemikhali, kwaye ayidliswanga nokuba ziiasidi okanye ialkaline.Njengoko i-particle size distribution of Platelet Alumina ilawulwa ngokuqinileyo, inokuvelisa umphezulu ocolekileyo kakhulu, inika ukusebenza okugqithisileyo njenge-abrasive.Ngoluhlu olukhulu lwezinto ezisetyenzisiweyo, iPlatelet Alumina ngumgubo onqabileyo okwazi ukwenza imisebenzi emininzi.

Tabular alumina powder

Tabular alumina powder

IiNgcaciso eziMgangatho zoBubungakanani beNcam

| Inqaku | Ukwabiwa kwamasuntswana (µm) | |||

| Ubuninzi besuntswana | Ubungakanani besuntswana | Ubungakanani besuntswana | Ubungakanani besuntswana | |

| 45 | 82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | 77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | <64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | <50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | <40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | <32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | <25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | <20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | <12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | <10.1 | 5.20±0.40 | 3.10±0.30 | 1.80±0.30 |

Umgangatho woMgangatho

| Uhlobo lwemveliso | Ubunzima obuthile | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | 3.90 | 99.0 | <0.20 | <0.10 | <1.00

|

Izinto eziluncedo zeAlumina Powder

1. Thelekisa enye i-powder ye-tabular, i-alumina ye-tabular powder ineempawu ezintle zokudibanisa.Njengomgangatho ophezulu wokunyibilika, ukuqina okuqinileyo, amandla aphezulu omatshini, ukumelana nokunxiba kakuhle, ukuxhathisa imichiza, ukuxhathisa kwe-oxidation kunye nokuxhathisa ukushisa njl.

2. I-Flat sheet shape yenza i-friction ibe mkhulu, iphucula isantya sokugaya kunye nokusebenza kakuhle, oku kunokunciphisa inani lomatshini wokusila, umsebenzi kunye nexesha lokugaya.

3. I-flat sheet shape yenza ukuba into yokugaya ingabi lula ukukrazula, izinga leemveliso eziqeqeshiweyo linokunyusa i-10% -15%.Umzekelo, umyinge we-silicon wafer ofanelekileyo we-semiconductor unokufikelela kwi-96% okanye ngaphezulu.

4. Ineempembelelo ezimbini ze-nano kunye ne-micro powders, umsebenzi ongaphezulu uphakathi, kungekhona nje ukudibanisa ngokufanelekileyo kunye namanye amaqela asebenzayo, kodwa kwakhona akulula ukudibanisa kunye nokuququzelela ukusabalalisa okusebenzayo.

5. Inonamathela kakuhle, impembelelo ebalulekileyo yokukhusela kunye nokukwazi ukubonisa ukukhanya.

6. I-alumina ye-tabular powder iphantse yacaca, ayinambala, kwaye inomgangatho osicaba kunye nogudileyo.Iikristale ezikhazimliswe kakuhle ziihexagons eziqhelekileyo.

7. I-alumina ye-tabular powder ingenziwa ibe ngumgubo obalaseleyo wokupholisa.

1. Ushishino lwezobuchwephesha: ukugaya kunye nokupolisha kwee-semiconductor monocrystalline silicon wafers, quartz quartz crystals, compound semiconductors (crystalline gallium, phosphating nano).

2. Imboni yeglasi: ukugaya kunye nokucubungula i-crystal, iglasi ye-quartz, i-kinescope glass shell shell, i-optical glass, i-liquid crystal display (i-LCD) ye-glass substrate, kunye ne-quartz crystal.

3. Ishishini lokugubungela: iingubo ezikhethekileyo kunye neefayili zokutshiza i-plasma.

4. I-Metal kunye ne-ceramic processing industry: izinto ezichanekileyo ze-ceramic, izinto eziluhlaza ze-ceramic ezifakwe kwi-sintered, i-high-grade high-high-temperature coatings, njl.

Umbuzo Wakho

Ukuba unayo nayiphi na imibuzo.Nceda uzive ukhululekile ukuqhagamshelana nathi.