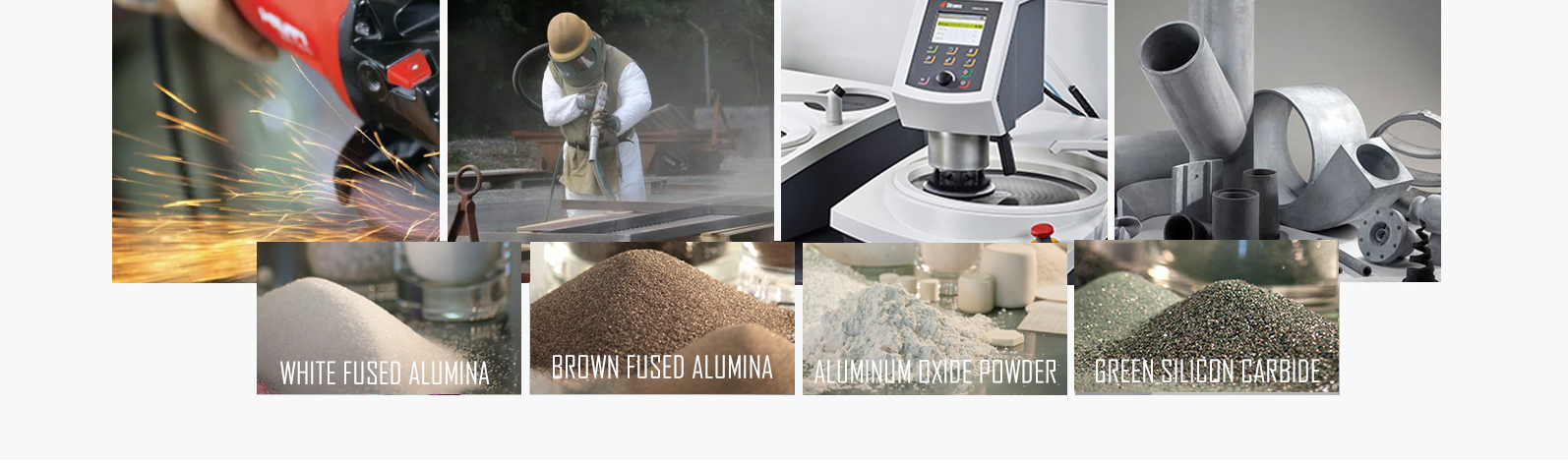

Iimveliso

F12-F220 White Fused Alumina Oxide Grits

I-alumina edibeneyo emhlophe

I-alumina edibeneyo emhlophe yenziwe nge-high-purity low-sodium alumina powder ngokunyibilika kwiqondo lobushushu eliphezulu, ukupholisa icrystallization, emva koko ukutyumza.Igrit ye-alumina edityanisiweyo emhlophe iphantsi kolawulo olungqongqo ukugcina ubungakanani bokuhanjiswa kweenkozo kunye nenkangeleko engaguqukiyo.

UWhiet Fused Alumina Properties

Imhlophe, i-crystal α ngaphezu kwe-99%, ubunyulu obuphezulu, ubunzima obuphezulu, kunye nokuqina okuphezulu, amandla okusika anamandla, ukuzinza okuqinileyo kweekhemikhali, kunye nokugquma okuqinileyo.

| Mohs ubulukhuni | 9 |

| Unizi lolwapho kuyiwa khona | 1.75-1.95g/cm3 |

| Ubunzima obuthile | 3.95g/cm3 |

| Ukuxinana komthamo | 3.6 |

| Idigri yokunyibilika | 2250℃ |

| Isidanga seRefractory | 2000℃ |

| Isetyenziselwa i-refractory, i-castable | |||||

| Iipropati | 0-1 1-3 3-5m/m | F100 F200 F325 | |||

| Ixabiso lesiqinisekiso | Ixabiso eliqhelekileyo | Ixabiso lesiqinisekiso | Ixabiso eliqhelekileyo | ||

| Ukuqulunqwa kwemichiza | Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

| Isetyenziselwa ukutshisa, ukuqhushumba, ukucola | |||

| Iipropati | Iinkozo | ||

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |||

| Ixabiso lesiqinisekiso | Ixabiso eliqhelekileyo | ||

| Ukuqulunqwa kwemichiza | Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

| Isetyenziselwa ukuthambisa, ukuthambisa, ukupholisha | ||||

| Iipropati | I-Micropowder | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000#050#1020 | |||

| Ixabiso lesiqinisekiso | Ixabiso eliqhelekileyo | |||

| Ukuqulunqwa kwemichiza | Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1.Ukuqhunyiswa kwesanti, ukupolisha kunye nokusila isinyithi kunye neglasi.

2. Ukuzaliswa kwepeyinti, i-coating-resistant coating, i-ceramic, kunye ne-glaze.

3.Ukwenziwa kwelitye leoli, ilitye lokugaya, ivili lokugaya, i-sandpaper kunye ne-emery cloth.

4.Ukuveliswa kweembrane zokucoca i-ceramic, iibhubhu ze-ceramic, iiplate ze-ceramic.

5.Ukuveliswa kolwelo lokupholisha, i-wax eqinile kunye ne-wax engamanzi.

6.Ukusetyenziswa komgangatho ongagungqiyo.

I-7.Ukugaya okuphezulu kunye nokupholishwa kweekristale ze-piezoelectric, i-semiconductors, insimbi engenasici, i-aluminium kunye nezinye izinyithi kunye nezingezona.

8.Iinkcazo kunye nokwakheka

Umbuzo Wakho

Ukuba unayo nayiphi na imibuzo.Nceda uzive ukhululekile ukuqhagamshelana nathi.