Idayimani "yokukrola" yeLaser: ukoyisa eyona nto inzima ngokukhanya

Idayimaniyeyona nto inzima kwindalo, kodwa ayizozacholo nje kuphela. Esi sixhobo sine-thermal conductivity ephindwe kahlanu kunobhedu, inokumelana nokushisa okukhulu kunye nemitha, inokudlulisa ukukhanya, i-insulate, kwaye inokuguqulwa ibe yi-semiconductor. Nangona kunjalo, ngala "namandla amakhulu" enza idayimani "eyona nto inzima" ukusetyenzwa - izixhobo zemveli azikwazi ukuyisika okanye zishiye iintanda. Kwakungekho de kwafika iteknoloji yelaser apho abantu ekugqibeleni bafumana isitshixo sokunqoba lo "kumkani wezinto eziphathekayo".

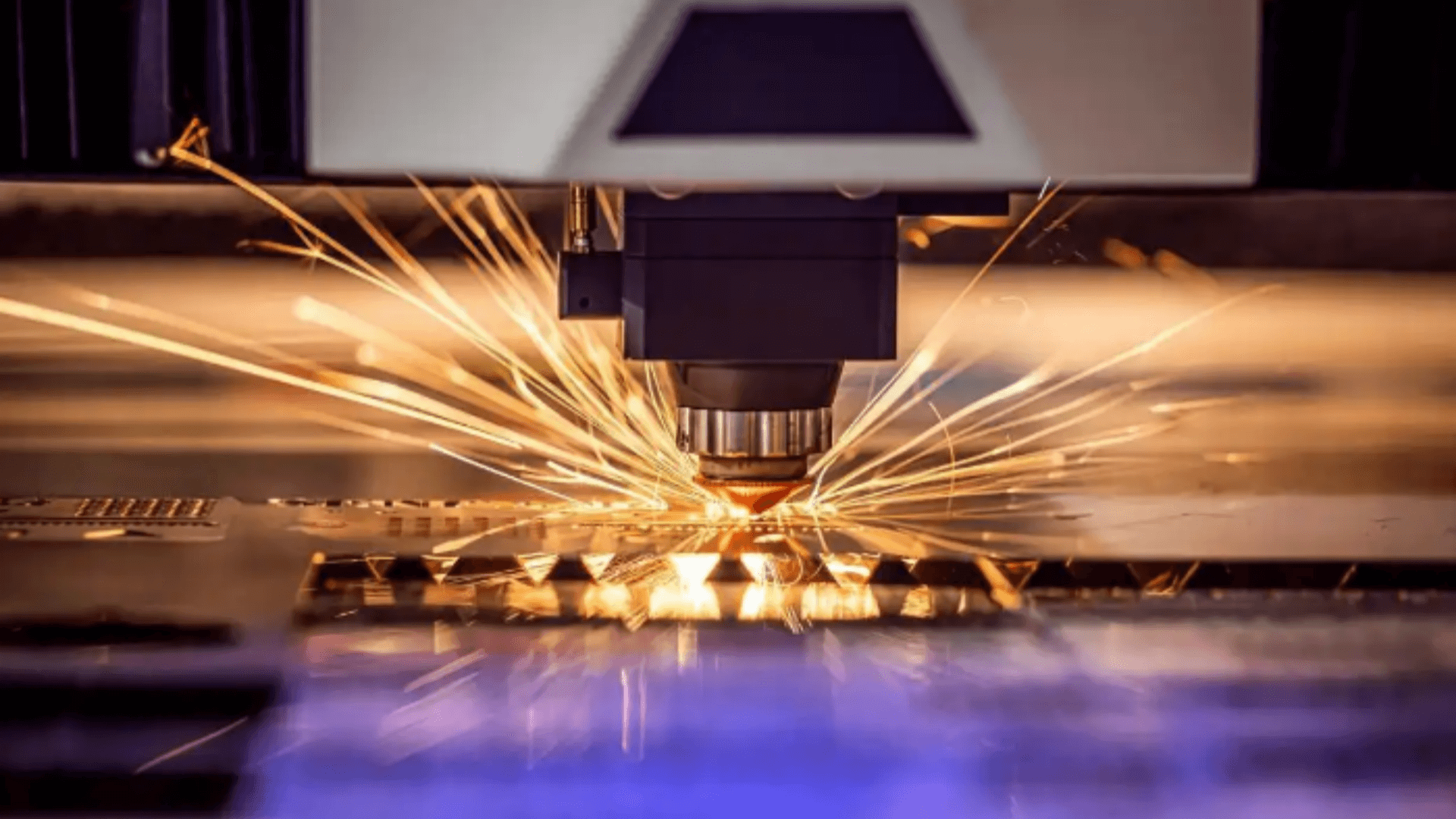

Kutheni i-laser "inokusika" idayimani?

Yiba nomfanekiso usebenzisa igilasi yokukhulisa amandla ukuze ugxininise ukukhanya kwelanga ukutshisa iphepha. Umgaqo we-laser processing diamond uyafana, kodwa uchaneke ngakumbi. Xa umqa welaser onamandla aphezulu ukhupha idayimani, i-"carbon atom metamorphosis" encinci iyenzeka:

1. Idayimani ijika ibe yigraphite: Amandla elaser atshintsha ubume bedayimane yomphezulu (sp³) ibe yigraphite ethambileyo (sp²), kanye njengedayimani ngokukhawuleza “iwohloka” ibe yilothe yepensile.

2. I-graphite "i-evaporated": i-graphite layer i-sublimates kwiqondo lokushisa eliphezulu okanye ifakwe yi-oxygen, ishiya amanqaku okucubungula achanekileyo. 3. Ukuphumelela okuphambili: iziphene Kwithiyori, idayimane egqibeleleyo inokucutshungulwa kuphela nge-ultraviolet laser (i-wavelength <229 nm), kodwa ngokwenene, iidayimane zokwenziwa zihlala zineziphene ezincinci (ezifana nokungcola kunye nemida yeenkozo). Ezi ziphene zifana “nemingxuma” evumela ukukhanya okuluhlaza okuqhelekileyo (532 nm) okanye i-infrared laser (1064 nm) ukuba ifunxe. Izazinzulu zinokuthi "ziyalele" i-laser ukuba iqingqe ipateni ethile kwidayimani ngokulawula ukuhanjiswa kwesiphene.

Uhlobo lweLaser: Indaleko ukusuka “kwiziko” ukuya “kwimela yomkhenkce”

Ukusetyenzwa kweLaser kudibanisa iisistim zolawulo lwamanani ekhompyuter, iinkqubo zamehlo eziphucukileyo, kunye nokuchaneka okuphezulu kunye nokubeka i-workpiece ezenzekelayo ukwenza iziko lophando kunye nemveliso. Ifakwe kwi-diamond processing, inokufezekisa ukusebenza ngokufanelekileyo kunye nokuchaneka okuphezulu.

1. Microsecond laser processing I-Microsecond laser pulse ububanzi ibanzi kwaye idla ngokulungele ukusetyenzwa rhabaxa. Ngaphambi kokuvela kwetekhnoloji yokutshixa imowudi, ii-laser pulses zazininzi kuluhlu lwe-microsecond kunye ne-nanosecond. Okwangoku, kukho iingxelo ezimbalwa malunga nokusetyenzwa kwedayimane ngokuthe ngqo kunye ne-laser ye-microsecond, kwaye uninzi lwazo lugxininisa kwintsimi yesicelo sokugqibela sokusebenza.

2. I-Nanosecond laser processing Nanosecond lasers okwangoku ithatha isabelo esikhulu semarike kwaye ineenzuzo zokuzinza okulungileyo, iindleko eziphantsi, kunye nexesha elifutshane lokucwangcisa. Zisetyenziswa ngokubanzi kwimveliso yeshishini. Nangona kunjalo, inkqubo ye-nanosecond laser ablation iyonakalisa isampuli, kwaye ukubonakaliswa kwe-macroscopic kukuba ukuqhutyelwa kuvelisa indawo enkulu echaphazelekayo ukushisa.

3. I-Picosecond laser processing Picosecond laser processing iphakathi kwe-nanosecond laser thermal equilibrium ablation kunye ne-femtosecond laser processing. Ubude be-pulse buyancipha kakhulu, obunciphisa kakhulu umonakalo obangelwa ngummandla ochaphazelekayo ukushisa.

4. Ukulungiswa kwe-laser ye-Femtosecond I-Ultrafast laser iteknoloji izisa amathuba okulungiswa kwedayimane, kodwa iindleko eziphezulu kunye neendleko zokugcinwa kwee-laser ze-femtosecond zinciphisa ukukhuthazwa kweendlela zokucubungula. Okwangoku, uninzi lophando olunxulumeneyo luhleli kwinqanaba lebhubhoratri.

Ukuqukumbela

Ukusuka "ukungakwazi ukusika" ukuya "kukrola ngokuthanda", iteknoloji ye-laser yenzeidayimani ayiseyo “vase” ebanjelwe elabhoratri. Ngokuphindaphindwa kobugcisa, kwixesha elizayo sinokubona: iitshiphusi zedayimani ezikhupha ubushushu kwiimfonomfono eziphathwayo, iikhomputha zequantum ezisebenzisa idayimani ukugcina ulwazi, kunye nezixhobo zedayimane zebhayoloji ezifakwe emzimbeni womntu… Lo mdaniso wokukhanya kunye nedayimani buyabutshintsha ubomi bethu.