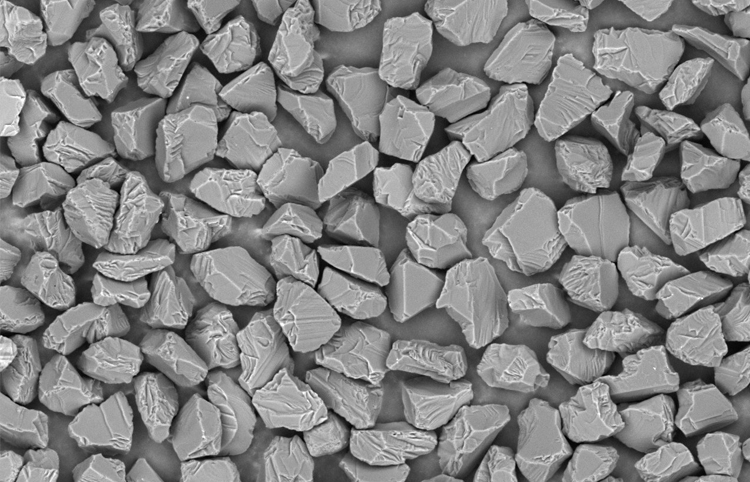

Njengoko imfuno ye-diamond micropowder iqhubeka nokunyuka, izicelo zayo kumashishini ahlukeneyo ziye zanda kakhulu. Ukusuka kwi-abrasives ukuya kwizixhobo zokusika, kwaye ukusuka kwi-electronics ukuya kwiyeza, i-diamond micropowder idlala indima ebalulekileyo kumacandelo amaninzi aphezulu. Nangona kunjalo, ukuhlangabezana neemfuno ezikhulayo zomgangatho, elinye lamanyathelo abalulekileyo kwinkqubo yayo yemveliso luhlelo lobungakanani bamasuntswana.

Emva kokwenza ibhola yokusila, ukutyunyuzwa, ukubunjwa, kunye nokucocwa okurhabaxa, i-diamond micropowder isafuna inyathelo elinye elibalulekileyo lokulungisa - ukuhlelwa kobungakanani bamasuntswana. Injongo yale nqanaba kukuqinisekisa ukuhanjiswa kobungakanani besuntswana elifanayo ngelixa ususa ngokupheleleyo amasuntswana angaphezulu.

Ngenxa yobume obuhle beidayimani micropowder, iindlela ezisekelwe kwi-sieve azikwazi ukufezekisa ukuchaneka okufunekayo. Ke ngoko, ukwamkela iindlela zesayensi, ezisebenzayo, kunye nezichanekileyo zokuhlela kubaluleke kakhulu. Ngokwandisa usetyenziso lwe-diamond micropowder kunye nokwanda kweemfuno zomgangatho kwimarike, abavelisi bahlala besebenzisa iindlela ezininzi zokuhlela. Oku kubandakanya ukuhlaliswa kwendalo, ukuhlelwa kwe-centrifugal, ukuhlelwa kokuphuphuma, kunye nokuhlelwa kwe-hydrocyclone.

Ukuhlelwa Kwendalo Yokumisa

Indlela yokumisa yendalo isekelwe kumgaqo wokuba, phantsi komxhuzulane okhethekileyo ofanayo, amasuntswana obukhulu obahlukeneyo ahlala ngemilinganiselo eyahlukileyo kulwelo. Kule ndlela, iinqununu zihlelwa ngokulawula ukuphakama kokumisa kunye nexesha.

Xa isuntswana lihamba kulwelo, iphenjelelwa ngamandla amathathu: amandla omxhuzulane wesuntswana ngokwalo, ukugcwala kolwelo, kunye nokuxhathisa okwenziwa sisiphakathi. Isantya sokumisa i-particle sixhomekeke kwizinto ezifana nommandla woqhagamshelwano phakathi kwe-particle kunye ne-medium, i-viscosity ye-fluid, kunye nokuxhatshazwa kwe-frictional experience yi-particle.

Ukuhlelwa kwe-Centrifugal

Ukuhlelwa kwe-Centrifugal kusebenza kumgaqo ofanayo kunye nokuhlaliswa kwendalo kodwa isebenzisa amandla e-centrifugal eveliswa yi-centrifuge ukwahlula i-micropowder. Kumasuntswana arhabaxa, ubunzima bawo obukhulu bubavumela ukuba bahlale ngokukhawuleza, kwaye ukuhlaliswa kwendalo kunokwahlula ngokufanelekileyo amasuntswana obungakanani obufanayo. Nangona kunjalo, kumasuntswana acolekileyo, isantya sokuzinzisa kancinci phantsi komxhuzulane sandisa kakhulu umjikelo wemveliso, sithatha indawo enkulu kunye nezikhongozeli. Amasuntswana e-Ultra-fine angade angaphumeleli ukwahlula ngokufanelekileyo ngenxa yentshukumo yeBrownian kunye nokuphazamiseka kwamasuntswana.

Ngokwahlukileyo, amandla e-centrifugal akhawuleza ukuhamba kwee-microparticles, ukukhawuleza inkqubo yokuhlelwa. Oku kwenza ulwahlulo lwe-centrifugal lusebenze kakuhle kakhulu kumasuntswana amahle, luphucula kakhulu ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Ngoko ke, abaninzi abavelisi badibanisa ukuhlaliswa kwendalo kunye nokuhlelwa kwe-centrifugal kuluhlu olupheleleyo lwe-powder-coarse-coarse. Le ndlela ye-hybrid ikhulisa ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

Ulwahlulo oluPhuphumayo

Ukuhlelwa kokuphuphumayo kunokuqondwa njengendlela yokubuyisela umva. Kuhlelo lokulinganisa ukuphuphuma, amanzi aziswa ezantsi kwesikhongozeli esicolekileyo. Njengoko amanzi eqhubela phezulu, isantya sawo siyancipha ngokuthe ngcembe kwaye sizinzile kwicandelo le-cylindrical phezulu.

Iincinci zedayimani zihamba ngokuchasene nokunyuka kwamanzi okunyuka, kwaye xa amandla obunzima kunye nokulinganisa kwamandla aphikisanayo, amaqhekeza obungakanani obuthile aya kuhlala emisiwe emanzini. Iincinci ezincinci ziya kuphuphuma kwisitya, ngelixa iinqununu ezinqabileyo ziza kuhlala kwicandelo le-conical. Ngokulungelelanisa izinga lokuhamba, abavelisi banokufumana iimveliso zobukhulu obuthile.

Ngelixa ulwahlulo lokuphuphuma luhamba kancinci kwaye lusebenzisa amanzi amaninzi, lubonelela ngokuchaneka okuphezulu kwaye lufuna izixhobo zokusebenza zezandla ezimbalwa xa kuthelekiswa nezinye iindlela. Izinto eziphambili eziphembelela ukusebenza kakuhle kobu buchule bubume bamasuntswana kunye nolawulo lwesantya sokuhamba. Iimilo zeengqungquthela ezingaqhelekanga zingabangela ukunyakaza okungahambelaniyo ngaphakathi kwe-fluid, ukuphazamisa inkqubo yokuhlela. Ukongezelela, ukulawulwa kokuhamba okungazinzanga kunokukhokelela ekuxubeni amaqhekeza amancinci kunye namancinci, ukukhusela ukuhlukana okuchanekileyo.

UHlelo lweHydrocyclone

Ukuhlelwa kweHydrocyclone kusebenzisa imigaqo yokumisa i-centrifugal ukwahlula amaqhekeza ngokukhawulezisa inkqubo yokwahlula ngokujikeleza ngesantya esiphezulu ngaphakathi kwe-hydrocyclone. Obu buchule busetyenziswa ngokubanzi kuhlelo olurhabaxa kunye nokuphelelwa ngamanzi emzimbeni kwemveliso. Iinzuzo zayo eziphambili ziquka isantya, ukulula, ukuphindaphinda okulungileyo, kunye nokutya okuqhubekayo. Isebenza ngokufanelekileyo kuzo zonke iimicropowder zedayimani ngaphandle kwezo zicolekileyo kune-2 microns. Nangona kunjalo, ayichanekanga kancinci kunezinye iindlela.

Ukukhetha iNdlela yoHlelo oluLungileyo

Indlela nganye yokwahlula ineengenelo zayo kunye nezinto ezisilela kuyo. Kwimveliso yangempela, abavelisi banokukhetha eyona ndlela ifanelekileyo ngokusekelwe kwiimfuno zabo ezithile. Abanye banokukhetha indlela yokuhlelwa enye, ngelixa abanye banokudibanisa iindlela ezininzi zokufumana iziphumo ezizezona zilungileyo. Ngokukhetha ngononophelo kunye nokudibanisa iindlela zokuhlela, iinkampani zinokuqinisekisa ukuba iimveliso zabo zedayimani micropowder ziyahlangabezana nemigangatho ephezulu yomgangatho.

Njengemarike yeidayimani micropowderiyaqhubeka nokuvela, uphuhliso lobuchwepheshe bokuhlela olukwinqanaba eliphezulu luya kubaluleka ekuhlangabezaneni nemfuno ekhulayo yeemveliso ezichane ngakumbi nezisebenzayo kuluhlu olubanzi lwamashishini.