Ukusetyenziswa kwe-α-alumina entshaiiseramikhi zealumina

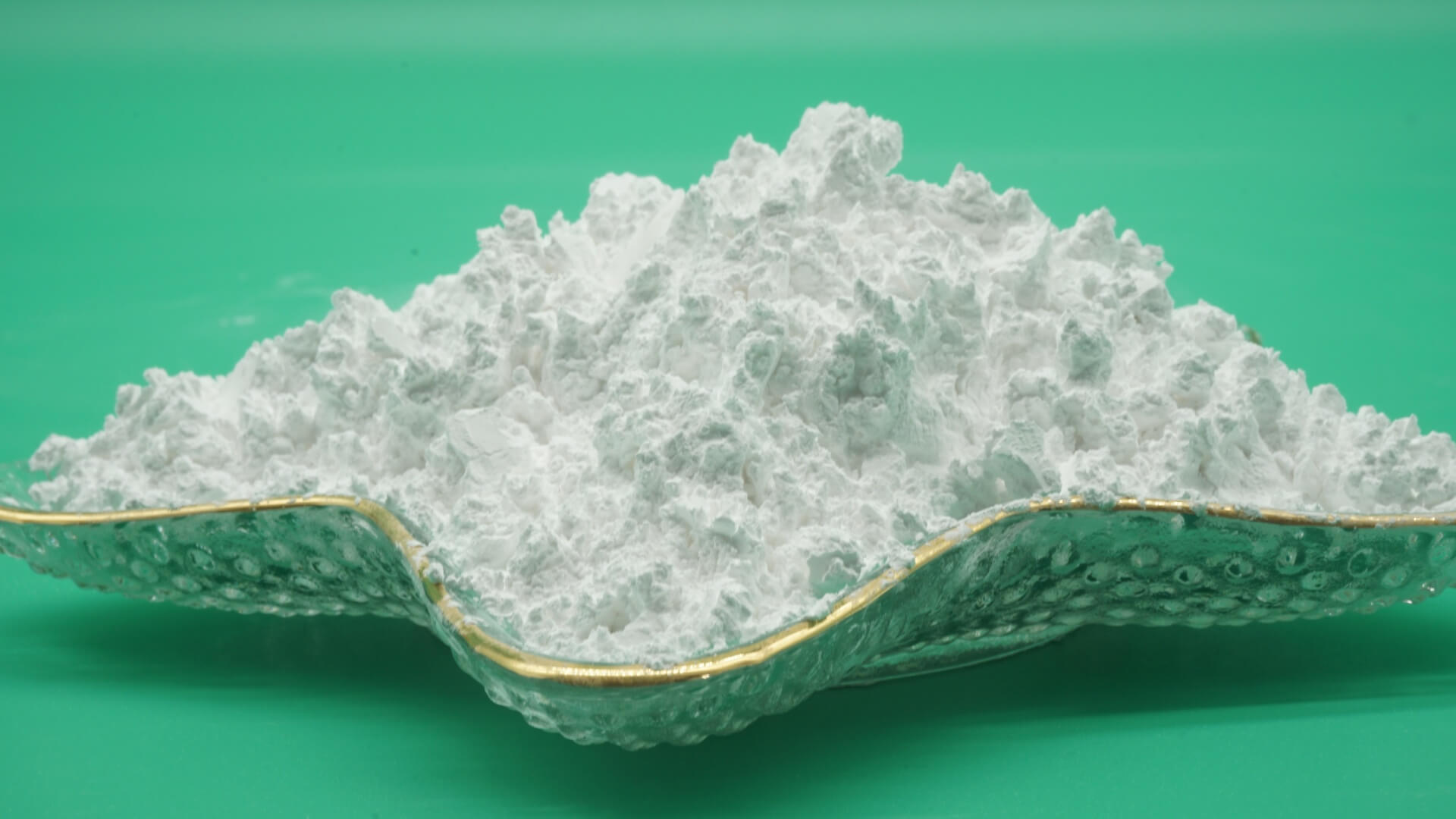

Nangona kukho iindidi ezininzi zemathiriyeli yeseramikhi emitsha, zinokwahlulwa ngokwesiseko ngokweendidi ezintathu ngokwemisebenzi yazo kunye nokusetyenziswa kwazo: iiseramics ezisebenzayo (ekwaziwa ngokuba ziiseramics zombane), iiseramics zolwakhiwo (ezikwaziwa ngokuba ziiseramics zobunjineli) kunye ne-bioceramics. Ngokwamacandelo ahlukeneyo eemathiriyeli ekrwada ezisetyenzisiweyo, zinokwahlulwa zibe ziiseramics ze-oxide, iiseramikhi ze-nitride, iiseramics ze-boride, iiseramics ze-carbide kunye neeseramics zetsimbi. Phakathi kwazo, i-alumina ceramics ibaluleke kakhulu, kwaye impahla yayo eluhlaza yi-α-alumina powder yezinto ezahlukeneyo.

I-α-alumina isetyenziswa ngokubanzi kwimveliso yezinto ezintsha ze-ceramic ngenxa yamandla ayo aphezulu, ubunzima obuphezulu, ukumelana nobushushu obuphezulu, ukuxhathisa ukunxiba kunye nezinye iimpawu ezigqwesileyo. Ayisiyonto nje umgubo ekrwada izinto eziphambili alumina ceramics ezifana substrates yesekethe ezidityanisiweyo, amatye anqabileyo, izixhobo zokusika, amathambo enziweyo, njl., kodwa ingasetyenziswa njengomphathi we-phosphor, izinto eziphambili zokuphikisa, izinto ezikhethekileyo zokusila, njl.

Ukusetyenziswa kwe-α-alumina kwi-ceramics esebenzayo

Iiseramics ezisebenzayobhekisa kwiiseramics eziphucukileyo ezisebenzisa umbane wazo, imagnethi, iacoustic, i-optical, i-thermal kunye nezinye iipropathi okanye iziphumo zokudityaniswa kwazo ukuphumeza umsebenzi othile. Zineempawu ezininzi zombane ezifana nokugquma, i-dielectric, i-piezoelectric, i-thermoelectric, i-semiconductor, i-ion conductivity kunye ne-superconductivity, ngoko banemisebenzi emininzi kunye nokusetyenziswa okubanzi kakhulu. Okwangoku, ezona ziphambili zisetyenziselwe ukusetyenziswa kwinqanaba elikhulu kukukhusela iiseramics zesekethe ezihlanganisiweyo kunye nokupakishwa, i-automotive spark plug insulating ceramics, i-capacitor dielectric ceramics esetyenziswa ngokubanzi koomabonwakude kunye neerekhoda zevidiyo, iiseramics zepiezoelectric ezinosetyenziso oluninzi kunye neekeramics ezinovakalelo kwiinzwa ezahlukeneyo. Ukongeza, zikwasetyenziselwa iityhubhu ezikhupha isibane soxinzelelo oluphezulu lwesodium.

1. I-Spark plug insulating ceramics

I-Spark plug insulating ceramics okwangoku kuphela kwenkqubo enkulu yeeseramics kwiinjini. Ngenxa yokuba i-alumina ine-insulation egqwesileyo yombane, amandla aphezulu omatshini, ukumelana noxinzelelo oluphezulu kunye nokuxhathisa ukothuka kwe-thermal, iiplagi ze-alumina ezikhuselayo zisetyenziswa kakhulu kwihlabathi. Iimfuno ze-α-alumina kwiiplagi ze-spark ziqhelekileyo eziphantsi kwe-sodium α-alumina micropowders, apho umxholo we-sodium oxide ngu-≤0.05% kunye nobukhulu be-particle 325 mesh.

2. Ii-substrates zesekethe ezidibeneyo kunye nezinto zokupakisha

I-Ceramics esetyenziswa njengezinto ze-substrate kunye nezinto zokupakisha ziphezulu kuneeplastiki kule miba ilandelayo: ukuxhathisa okuphezulu kwe-insulation, ukunyanzeliswa kweekhemikhali eziphakamileyo, ukutywinwa okuphezulu, ukuthintela ukungena komswakama, akukho reactivity, kwaye akukho ngcoliseko kwi-silicon ye-ultra-pure semiconductor. Iipropati ze-α-alumina ezifunekayo kwii-substrates zesekethe ezidibeneyo kunye nezixhobo zokupakisha zezi: i-coefficient yokwandisa i-thermal 7.0 × 10-6 / ℃, i-thermal conductivity 20-30W / K · m (iqondo lobushushu begumbi), i-dielectric rhoqo 9-12 (IMHz), ilahleko ye-dielectric 3 ~ 10-4 (I-10 MHz , i-2 Ω-4 (i-10 MHz), i-resistance ye-volume Ω Ω Ω Ω Ω Ω Ω (10 MHz 1 MHz) .

Ngokusebenza okuphezulu kunye nokudityaniswa okuphezulu kweesekethe ezidityanisiweyo, iimfuno ezingqongqo zibekwe phambili kwii-substrates kunye nezixhobo zokupakisha:

Njengoko isizukulwana sobushushu se-chip sikhula, kufuneka i-thermal conductivity ephezulu.

Ngesantya esiphezulu se-computing element, i-dielectric ephantsi rhoqo iyafuneka.

I-coefficient yokwandisa i-thermal iyadingeka ukuba isondele kwi-silicon. Oku kubeka iimfuno eziphezulu kwi-α-alumina, oko kukuthi, iphuhlisa kwicala lokucoceka okuphezulu kunye nokulunga.

3. Isibane esiphezulu soxinzelelo lwesodium

Iiseramics ezintleyenziwe nge-high-purity ultrafine alumina njengemathiriyeli ekrwada ineempawu zokumelana nobushushu obuphezulu, ukumelana nokugqwala, ukugquma okulungileyo, ukomelela okuphezulu, njl. I-polycrystalline ecacileyo eyenziwe nge-alumina ecocekileyo enomlinganiselo omncinci we-magnesium oxide, i-iridium oxide okanye izongezo ze-iridium oxide, kwaye yenziwe yi-atmospheric sintering kunye ne-hot sintering, inokumelana nokuhlwa komphunga we-sodium enobushushu obuphezulu kwaye inokusetyenziswa njengezibane ezikhupha ukukhanya kwe-sodium ezinoxinzelelo oluphezulu olunokukhanya okuphezulu.

Ukusetyenziswa kwe-α-alumina kwi-ceramics yesakhiwo

Njengezinto ze-inorganic biomedical, imathiriyeli ye-bioceramic ayinazo iziphumo ebezingalindelekanga ezinetyhefu xa kuthelekiswa nemathiriyeli yesinyithi kunye nemathiriyeli yepolymer, kwaye inokuhambelana kakuhle kwe-biocompatibility kunye nokuchasana nokubola kunye nezicubu zebhayoloji. Baye baxatyiswa ngakumbi ngabantu. Uphando kunye nokusetyenziswa kweklinikhi yezixhobo ze-bioceramic ziye zaphuhliswa ukusuka ekutshintshweni kwexesha elifutshane kunye nokuzaliswa kukufakelwa okusisigxina kunye nokuqinileyo, kunye nokusuka kwizinto eziphilayo ze-inert ze-biological ukuya kwizinto ezisebenzayo ze-biologically kunye ne-multiphase composite materials.

Kwiminyaka yakutshanje, i-porousiiseramikhi zealuminasele zisetyenziselwe ukwenza amalunga okwenziwa kwamathambo enziweyo, amadolo enziweyo, iintloko ze-femoral ezenziweyo, amanye amathambo okwenziwa, iingcambu zezinyo ezenziweyo, izikrufu zokulungisa amathambo, kunye nokulungiswa kwe-corneal ngenxa yokunganyangeki kwemichiza, ukumelana nokunxiba, ukuzinza okuhle kobushushu obuphezulu, kunye neempawu ze-thermoelectric. Indlela yokulawula ubungakanani bepore ngexesha lokulungiswa kweeseramikhi ze-alumina ezinobuncwane kukuxuba amasuntswana e-alumina yobungakanani bamasuntswana ahlukeneyo, ukufakwa kwe-foam, kunye nokutshiza komise amasuntswana. Iipleyiti ze-aluminiyam nazo zinokuthi zenziwe nge-anodized ukuvelisa i-nano-scale-scale microporous channel-type pores.