Iimveliso

Metal abrasive Steel Grit Blast Media

UMHLABA WENKANTSI

Le media ndlongondlongo isetyenziselwa ukuqhushumba kunye nokuhluba intsimbi kunye ne-foundry metals. I-Steel Grit ivelisa ngokufanelekileyo i-etching kwiintsimbi eziqinileyo zokuncamathela okungcono kwengubo ezibandakanya iipeyinti, i-epoxy, i-enamel kunye nerabha. Usetyenziso lubandakanya ukulungiswa kwemoto kaloliwe, ukususwa kokudanyaza, iibhulorho eziqhumayo, iinxalenye zentsimbi kunye nokufakwa kwezicelo zeshishini.

| Iimveliso | Intsimbi yentsimbi | |

| Ukuqulunqwa kwemichiza | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Ukuqina | Ukudubula kwentsimbi | I-GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Ukuxinana | Ukudubula kwentsimbi | 7.6g/cm3 |

| Ubume beMicro | Isakhiwo seMartensite | |

| Imbonakalo | Amasuntswana aHollow aSpherical<5% Iqhekezana eliqhekeka <3% | |

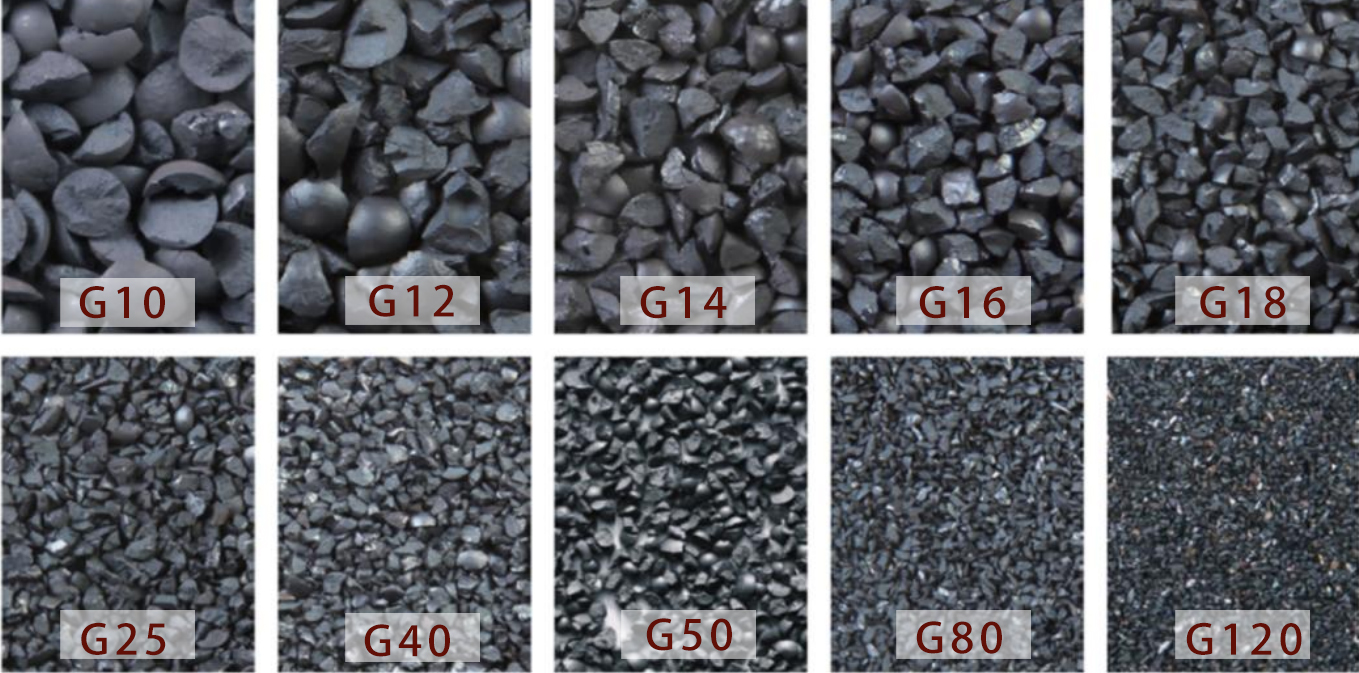

| Uhlobo | G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 | |

| Ububanzi | 0.2mm, 0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm | |

Isicelo seNsimbi yeNsimbi

1.Ukulungiswa komphezulu: Iigrits zensimbi zisetyenziselwa ukulungiswa kwendawo ngaphambi kokufaka iingubo, iipeyinti, okanye i-adhesives. Basusa ngokufanelekileyo i-rust, isikali, iingubo ezindala, kunye neengcoliseko ezivela kwiindawo zetsimbi, ziqinisekisa ukunamathela ngokufanelekileyo kwezixhobo ezilandelayo.

I-2.I-Rust kunye nokususwa kwe-Corrosion: I-grits yensimbi isetyenziselwa ukususa i-rust enzima, i-corrosion, kunye ne-mill scale kwi-metal surfaces, ngakumbi kumashishini afana nokwakhiwa kweenqanawa, ukugcinwa kolwandle, kunye ne-structural steel fabrication.

I-3.Ukulungiselela i-Welding: Ngaphambi kwe-welding okanye ezinye iinkqubo zokujoyina, i-grits yensimbi ingasetyenziselwa ukucoca kunye nokulungisa iindawo, ukuqinisekisa ukuba i-weld eqinile kwaye ihlambulukile.

I-4.I-Concrete kunye ne-Stone Surface Preparation: I-Steel grits ingasetyenziselwa ukucoca nokulungisa iindawo eziphathekayo kunye namatye, njengeeprojekthi zokubuyisela, apho ukususwa kweengubo ezindala, amabala, okanye ukungcola kuyimfuneko.

5.Ukukrolwa kwentsimbi: Ngelixa izithonga zentsimbi ziqhele ukusetyenziselwa ukukroba, iigrits zentsimbi zingasetyenziselwa le nkqubo. Ukukroba i-shot peening kubandakanya ukubhobhoza umphezulu ngamasuntswana abrasive ukuphembelela uxinzelelo olucinezelayo, olunyusa amandla ezinto kunye nokumelana nokudinwa.

I-6.I-Deburring kunye ne-Deflashing: I-Steel grits isetyenziselwa ukususa ii-burrs, ii-edges ezibukhali, kunye nezinto ezigqithisiweyo ezivela kwiindawo zetsimbi, ngakumbi kwiinkqubo zokuvelisa apho ukuchaneka kunye nokugudiswa kuyadingeka.

Izicelo ze-7.Foundry: Iigrits zensimbi zisetyenziselwa ukucoca kunye nokulungiselela iindawo zokuphosa, ukususwa kwe-mold kunye ne-core, kunye nonyango lwesinyithi jikelele. I-8.I-Surface Profile: Iigrits zensimbi ziqeshwe ukudala iiprofayili ezithile zomhlaba, ngakumbi kumashishini afana nokwakhiwa kunye nokwakhiwa kweenqanawa. Ezi profayili ziphucula ukunamathela kokutyabeka kwaye zibonelele ukubamba ngcono kwiindawo ezichasene ne-slip.

I-9.I-Stone Cutting and Etching: Kwimizi-mveliso yokwakha kunye nesikhumbuzo, iigrits zetsimbi zisetyenziselwa ukusika kunye nokudibanisa amatye kunye nezinye izinto ezinzima, ukudala ukuyila okuyinkimbinkimbi kunye neepatheni.

I-10.Ishishini le-oyile negesi: Iigrits zentsimbi zisetyenziselwa ukulungiswa komphezulu kwishishini leoli negesi, njengokucoca imibhobho, iitanki, kunye nezinye izixhobo.

I-11.Ishishini le-Automotive: Iigrits zentsimbi zingasetyenziselwa ukuhlubula ipeyinti kunye neengubo ezivela kwiindawo zemoto, ukulungiselela iindawo zokulungisa okanye ukubuyisela.

Kubalulekile ukuba uqaphele ukuba ukhetho lobungakanani obufanelekileyo begrit yentsimbi, ukuqina, kunye nezinye iinkcukacha kuxhomekeke kwisicelo esithile kunye nokugqitywa komhlaba ofunekayo. Iimpawu eziqhekezayo zeegrits zetsimbi zibenza zibe zixhobo ezixabisekileyo kwimisebenzi efuna ukususwa kwezinto ezinamandla kunye nokuguqulwa kwendawo.

Umbuzo Wakho

Ukuba unayo nayiphi na imibuzo.Nceda uzive ukhululekile ukuqhagamshelana nathi.